Rhodium, which has the chemical symbol Rh, is a white-colored precious metal. It was discovered in 1803 by the English chemist William Hyde Wollaston (he also discovered palladium a year before that). It was named after the pink color of the rhodium compounds – the name comes from the Greek rhodon, which means pink.

Rhodium (along with palladium and ruthenium) belongs to the light platinum group metals. The entire group of platinum metals (the so-called PGMs – Platinum Group Metals) includes three heavy platinum group metals: osmium, platinum, and iridium. Rhodium is characterized by its impressive chemical stability and durability, moderate electrical and thermal conductivity, and strong hardness. It belongs to the noble metals. Its melting point is very high (about 3,567°F – in comparison, gold melts at 1,948°F). It slightly dissolves in only the strongest acids.

Rhodium and its use

Rhodium and the rest of the group of PGMs are most commonly used in industrial production. Palladium, ruthenium, and rhodium are also sometimes used for plating in jewelry making. Even though this makes up only a minority of their use, to us, it’s more important.

The plating can be done galvanically in a galvanic bath or using a pen plating system. However, pen plating is really only used for small areas and fine corrections. There are two rhodium solution types for galvanic baths: white and black. In the KLENOTA atelier, we only use the white rhodium solution, which creates a beautiful silvery white luster. When black rhodium is used, the jewelry gets an anthracite black, glossy surface.

Why is plating used for jewelry?

Galvanic rhodium plating is used for white gold and silver jewelry. In silver jewelry, the rhodium layer significantly increases their luster, and it also protects them against natural oxidation. Oxidation, the blackening that can occur in silver jewelry, is caused by humidity, air, and sweat. You still have to exert caution, though – even rhodium plating won’t be able to fully protect your silver jewelry from excessive sweat.

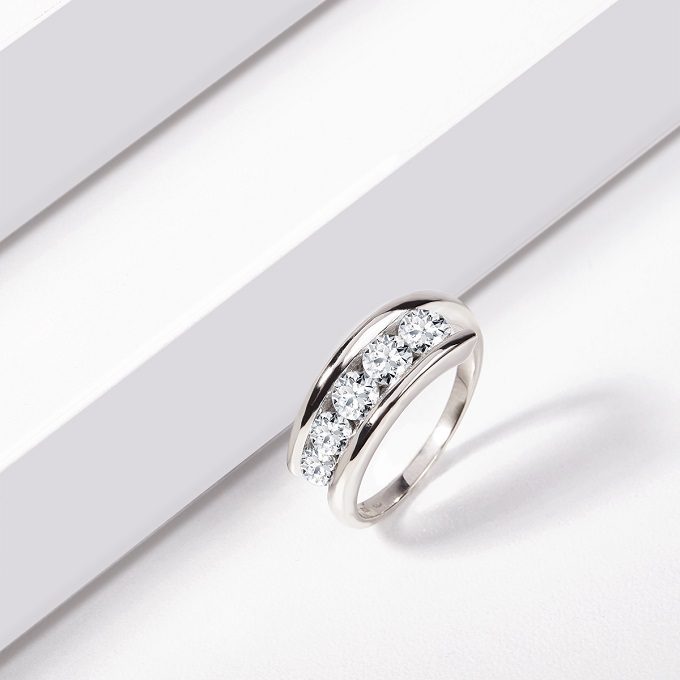

In white gold, using rhodium plating is, on the other hand, a trend. Contrary to silver, gold is not prone to color-changing. White gold is naturally yellowish, so after plating, we get the ideal shining white jewelry. However, rhodium does have a protective function for gold as well. If a piece of jewelry is scratched, usually only the layer of rhodium has to be buffed to fix it, so the client loses less gold than when unplated jewelry is refurbished. The total losses aren’t very large – its hundredths or tenths of a gram at maximum (depending on the size of the jewelry and the extent of the damage).

Remember – all plating eventually wears off. The rate of wear-and-tear might be lower if you don’t wear plated rings on adjacent fingers. Nevertheless, it’s still a good idea to renew the plating. Your jewelry will always look good as new.

The principle of galvanic plating

Galvanic plating is a process in which a direct electrical current makes metal ions from a solution or electrode (anode) move to a second electrode (cathode) to produce a coating. So, either an anode from the desired metal is used, which gradually dissolves, causing the metal ions to transfer from it to the cathode. Or, a solution is used – the metal ions are dispersed in a solution for the plating process. The second method is used in jewelry making.

Solution plating includes several steps: degreasing, surface activation, and the galvanic plating itself – and rinsing with water after each step. The surface activation is not totally necessary (it mainly serves to remove the thin oxidized layer from the surface of objects, and it improves the quality of the final plating). So, we need a machine with 4 to 6 containers for the whole process. Before plating, the jewelry should undergo an ultrasonic cleaning so there’s no residue of polishing cream or other impurities.

The process of rhodium plating jewelry

To plate KLENOTA jewelry, we use a machine with 4 containers. There are chemicals in two containers, and the remaining two contain distilled water for rinsing the jewelry. Anodes are dipped in the containers with chemicals. We use several hooks made from conductive metals (like copper or silver) as a cathode. The jewelry to be plated hangs on the hooks.

The first chemical substance used in the plating process is the so-called degreaser (or electrocleaner), which is in the first container. The degreasing solution is made with a special salt dissolved in water (e.g. from sodium hydroxide). Using the solution, we remove all impurities, dust, organic residues, and grease from the jewelry that might prevent a perfect plating. An electric current at a 2.5-3V voltage is used for degreasing. We clean the object in the beaker for 30 seconds to 1 minute. After degreasing, the object is rinsed in a container with distilled water. Electricity is not needed for this step.

The plating liquid is in the third container. The plating liquid itself is basically a solution in which the desired metal particles or compounds are dispersed. A rhodium solution consists of sulfuric acid that contains rhodium sulfate. Another solution that can contain rhodium ions is rhodium chloride. Plating is done using a 2.5-3V electric current. We keep the jewelry dipped in the beaker for 30 seconds to 1 minute, depending on the fineness of the object and the precise voltage. When this step is finished, we dip the jewelry into the last water-filled beaker several times. This water doesn’t have to be distilled.

The key to high-quality plating is a clean piece of jewelry. The rinsing baths should contain no impurities and need to be changed often. The same applies to the degreasing bath – a thorough degreasing of the jewelry is essential. In the rhodium bath, the concentration of rhodium needs to be checked. If it is low, the jewelry will not be evenly plated, and the color of the original metal will shine through. Therefore, the solution needs to be adjusted or – in a perfect case – completely changed.

Mistakes in galvanic plating

Galvanic plating could feel a little like alchemy before the right parameters are correctly set. If the voltage is too high, the jewelry will turn black very easily. In that case, the jewelry would have to be burnished and re-plated. If repeated rhodium plating occurs, the plated layer will be too thick, it’ll be poor quality, and it’ll eventually start to peel off. Repeated rhodium plating can also make the plated layer become less compact and uniform, potentially causing stains to occur. Therefore, it’s better to grind down the original layer, burnish the jewelry, and repeat the rhodium plating with a clean surface. Stains can also appear on newly plated jewelry if the jewelry wasn’t properly cleaned or degreased or if the oxidized layer was not removed. Jewelry in this kind of shape will need to be ground down and plated again.

A major (dis)advantage of galvanic plating is that rhodium will reveal all the imperfections on the surface of the jewelry. Thus, plating can emphasize scratches, mistakes in the cast which were not repaired, or a poorly burnished surface. With a high-quality plating, though, all these defects can be fixed and the client will get a perfect piece of jewelry.

Where is rhodium found in nature?

Earth’s crust only contains 0.001 ppm, or 0.0000001%, of rhodium. Rhodium is mainly found in nature in its pure form, always consists of one stable isotope (103Rh), and will always be found with other platinum group metals. Minerals that contain rhodium include cuprorhodsite, cherepanovite, polkanovite, and miassite. The largest mines are in the Republic of South Africa and the Ural Mountains, and they are both platinum group mines. Other deposits are found in South America, where rhodium is included in gold-bearing minerals. In Canada, it is found in nickel minerals.

Rhodium is very rare. Only about 25 tons are mined every year. This is, of course, reflected in its price. The high price is mainly governed by the demand of the automotive industry where rhodium, along with platinum and palladium, is used in catalytic converter production. It reached its maximum value in 2008 when the average price for a troy ounce (31.1 g) was around $6,530. The price on the market today (June 2019) is over $2,898 for a troy ounce. Compared to gold, silver, platinum, or palladium, rhodium is the most expensive metal.

What else is used in jewelry plating and how it’s done

Plating changes how the jewelry looks and makes the surface more resistant to damage. It can also be helpful for allergy sufferers: the allergenic metal is hidden under the surface of another metal, so it doesn’t irritate the skin. Besides rhodium, jewelry can be galvanically plated using gold, silver, palladium, ruthenium, or platinum. Gold plating can be done in all the three common colors of gold – yellow, white, and rose. However, gold plating and silver plating are both pretty complicated, and jewelry stores don’t usually offer these options. Solutions for galvanic plating with gold and silver contain cyanide. So, there are much more rigid safety measures in place for working with these solutions. We can also come across copper and nickel solutions; however, these mainly serve for base layers before the final plating.

Other methods of changing the surface color of the original metal include controlled oxidation, the CVD method (a chemical reaction of gas with the surface of the metal), or patina. For example, silver is patinated with sulfur to get a black-brown look. We can do this in our atelier as well. Gold jewelry with a black surface can be created in several ways: by galvanic plating using black rhodium or ruthenium, by the CVD method using carbon, or by controlled oxidation using cobalt and copper. A patina can also be done, but it is not as durable.

One fun fact for the end: Paul McCartney received a special award from the Guinness Book of World Records in 1979. However, silver, gold, or even platinum wasn’t good enough for this occasion. McCartney was awarded a rhodium disc for being the world’s best-selling songwriter and to celebrate his contribution to the world of music! (In fact, the disc is really a rhodium-plated gold disc.)